Although not a navy troop, Bondo nevertheless has had a lifelong

fascination with flying boats, maybe because his dad had long ago owned a

Chris-Craft Riviera runabout which seemed, at least to an impressionable

twelve-year-old, to “come up on the plane” and “fly” over the waters of new

York’s Lake Chautauqua.

This boy modeler’s been accumulating flying boat and amphibian kits for at least

thirty-five years, from the WWI Felixstowe through WWII’s Coronados, Catalinas,

Mariners and Mars, from the Korean War’s Albatrosses, all the way to the Marlins

and (again) Albatrosses of the Southeast Asia conflict. In between the Korean

and Vietnam wars came the unarguably piece de resistance of flying boats and,

sadly, pioneering Martin Aircraft’s last gasp, the all-jet, cutting edge P6M.

Conceived as a high speed mine layer, the SeaMaster suffered the agony of being

conceived, designed and tested at a time of very high strategic planning flux

among U.S. armed services. The Air Force strongly objected to a sophisticated,

large, multijet-engined navy airframe treading on its sacred “turf,” strategic

bombing. Even within the P6M’s own service branch, nuclear-powered, ICBM-armed

submarines, and the advent of long-ranging nuclear aircraft carriers were

obstacles that turned out to be showstoppers. The SeaMaster “died” on 21 August

1959. Although Martin Aircraft had other, non-aircraft projects in work, the

loss to its large flying boat manufacturing facility at Middle River, Maryland

was catastrophic. And, to top off a really grim situation, the Navy unbelievably

disregarded aviation history by directing that all P6M airframes, manufacturing

fixtures and blueprints be destroyed. No complete SeaMaster airframes remain

today; aviation enthusiasts, including us modelers, are also victims of that

same, shocking decision.

Kit Chronology

Although there might have been a Japanese injected model of the

SeaMaster, the most well-known kits today are an injected, “box scale” (1/136)

effort by Revell in the Fifties (H-244) and the 1/72 Seventies Airmodel vacuform

kit from Germany. The Airmodel kit is typical of vac technology of the time:

thin plastic, male molding, rounded edges, panel line “trenches”, poor clear

parts, etc. Granted, the kit is doable by a competent scratchbuildering modeler,

but prepare for a plastic “beating.”

Enter Arnold and the good guys at Hong Kong’s Anigrand Models, and now it’s a

whole new ballgame. I had for all intents given up hope that there would ever be

a 1/72 P6M kit to replace the Airmodel vac, and I had even cut out the parts and

sanded trailing edges. In fact, Matthias Simon, the niceguy new principal of

Airmodel has been slowly trying to upgrade the old, more desirable releases by

doing resin details and refinements, and he had already kindly sent me gratis a

redone canopy and seats for the SeaMaster. I’m very sorry for Matthias to have

to report that the, granted, much more expensive Anigrand version of the P6M

simply blows any previous efforts, by anyone, out of the water. Unless, that is,

“practice bleeding” is the modeler’s raison d’etre.

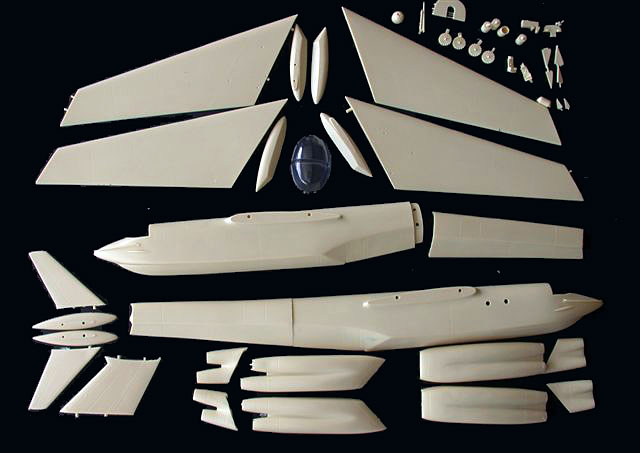

Anigrand’s all-resin release is perhaps the largest undertaking

yet by this firm, and that presages future releases of even more interesting

subjects, such as the C-124 that is to be released in October 2006. Woooweeeeee!!!

Molding

Smooth, clean castings, very reminiscent of Planet and other

Czech resin releases. Engraving is crisp, ever so slightly more aggressive than,

say, on 1/48 Tamiyagawa kits. But, I think we’re dealing here more with the

master modeler’s personal style than what the real scale panel line width/depth

would be. In any event, this machs nichs to this modeler. Some small bubbles

have occurred on my copy, especially at the aft edge of the canopy “hole”. Some

of the bubbles luckily have that tissue-thin covering over the bubble, so I plan

to merely fill in with CA+ on the bubbles’ backsides. A few additional bubbles

were also found at the end of the afterburner cones. The flying surfaces are

very thin and generally warp-free. Engine nacelle mounting holes in the top

surface of the wings should not be confused with bubbles!

Each half of the long fuselage is, in turn, broken into two

components, with the break well back on the empennage. Alignment holes and pegs

are provided, along with a substantial overlapping join area; no weak butt

joints, as is the custom with Collect-Aire kits! The delicate spray chines on

either side of the nose area are nicely represented, but you might want to

reinforce them with a thin fillet of CA.

Details

The builder is given the choice (and parts) of doing the

prototypical XP6M-1 with the prominently separated, long afterburner sections

and “cage-style” canopy, or the definitive production version, the P6M-2, with

the more outwardly canted, more faired-in engine nacelles and bulbous, “cleaner”

canopy. Cursory fitting of the separate bottom aft afterburner sections reveals

that this is a likely place for filling and sanding.

A note regarding the two possible versions: Anigrand seems to have missed the

fact that the production P6M-2 featured a revised wing with essentially no, or

very little, anhedral. That is, the wings no longer “drooped” as much as in the

XP6M-1s but were much straighter all the way out to the wingtip floats. This

change caused the whole P6M-2 airframe to, when at rest in the water, weirdly

cant to one wingtip float or the other depending on balance. Builders will have

to make their own changes in the wing joint to accommodate whichever version

they choose.

Additionally, Anigrand has made no provision for the XP6M-1's thinner “teardrop”

tailplane fairing at the top of the vertical fin, but has only addressed the

“fatter” profiled fairing of the production P6M-2. The early version builder is

on his own here.

Cockpit

Small parts consist of the aft bulkhead, seats (with cast-in

harnesses), consoles, instrument panel and control yokes. Both canopy versions (vacuformes)

are provided; they’re clear, clean, with petite engraving. When doing the

production version with the large, unframed canopy area on top, the builder

might want to “busy-up” the cockpit by adding some miscellaneous PE panels from

the spare parts box. Bondo’s copy unfortunately arrived with large portions of

the cockpit floor broken off and missing. Scratchbuild City; life’s too short!

Other Details

Included are engine compressor faces and exhaust tubes. Left out

are the late engine nacelle modifications such as intake fences, spoiler strips

and prominent intake splitter plates.

Beaching Gear

What beaching gear??

I’m surprised that so prominent an assembly has been ignored by

Anigrand. The builder is faced with just resting the model on a table or base,

doing the water jell bit, building a simplistic cradle ala a ship model, or

doing as employees of Bondo industries are: scratchbuilding the complicated,

“busy” gear from available color pix. To be fair to Anigrand, Arnold just may

offer the distinctive, large yellow rig in the future. I wish it had been

included up front, even at an increased price.......

Decals

No decals were in my kit, and a quick email to Hong Kong saw

said sheet at my door in less than two weeks. The sheet features the distinctive

prototype SeaMaster script logo, national markings and a few stencils for both

versions; I think I’ll go the aftermarket route.

Instructions

Both sides of an 8 1/2 X 11 inch sheet. Perspective parts blowup

with individual callouts and a short history. On the reverse side are two-view

B&W drawings of both versions showing color delineation and decal callouts.

A VERY welcome release and well worth the righteous bucks for everyone but

modeling masochists. No problems that can’t be handled tut suite by most

builders, the beaching trolley excepted. Arnold REALLY needs to offer this

feature!

Highly recommended.

Review Text and Images Copyright © 2005 by

Phil Brandt

Page Created 23 August, 2005

Last updated 25 August, 2006

Back to HyperScale Main Page

Back to Reviews Page

Home | What's

New | Features

| Gallery |

Reviews | Reference

| Forum

| Search