|

Messerschmitt

Bf 109G-6

Replacement Cockpit

Meteor

Productions

|

S u m m a r

y |

|

Catalogue Number, Description and Price: |

CEC32083

Bf 109G-6 Super Detailed Cockpit with molded on seatbelts USD$21.99

CEC32090

Bf 109G-6 Super Detailed Cockpit with posable seatbelts USD$24.99

|

| Scale: |

1/32 |

|

Contents and Media: |

Both Sets:

14 parts in grey resin, one clear acetate sheet, 1 x 5cm rubber hose

Plus with CEC32090 only: 1 sheet of flexible resin with

harness and rudder toe straps. |

| Review

Type: |

FirstLook and

Construction |

|

Advantages: |

Excellent

detail; great improvement over kit cockpit; innovative

"flexible resin" positionable harness option; perfect

fit; straightforward engineering/construction; acetate

instruments; detailed instructions. |

|

Disadvantages: |

Care required

removing cockpit casting block; flexible resin harness material

tricky to cut out; a few challenging details (owing to small

size); some fabrication of minor parts required. |

|

Recommendation: |

Highly Recommended

|

Reviewed by

Brett Green

HyperScale is proudly sponsored by Meteor

Productions

Hasegawa's 1/32 scale Messerschmitt Bf 109G-6 is an

impressive and accurate model. The cockpit is quite adequate for a stock

kit, but many modellers will crave more detail. The large scale will

certainly reward any extra effort in this area.

Cutting Edge is the first company to release a

replacement cockpit. Two versions are available - one with a resin harness

cast onto the seat and another with a flexible harnesses supplied

separately.

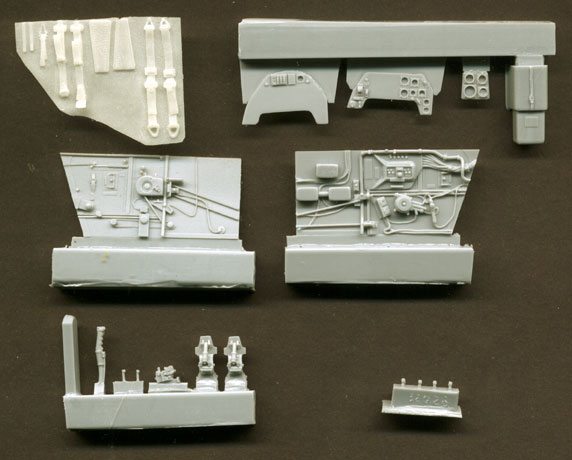

Both cockpit sets include fourteen parts in grey resin

(plus three spare parts) and one acetate sheet with printed instruments. A

short length of rubber tube is also included. Interestingly, Cutting Edge

manage to deliver much improved detail compared to the Hasegawa kit with a

smaller parts count. The resin is perfectly cast on both of my

samples.

There were many minor detail and colour variations between Bf

109G-6 cockpits due to its long production run and chaotic manufacturing

environment. Cutting Edge's set seems to represent a mid-late production

Bf 109G-6 cockpit in factory configuration. The most obvious indicator is

the Revi 16B gunsight, as used in later Gustavs.

The largest resin part in both sets is the cockpit

tub comprising the floor, rear wall, firewall, control column

boot and seat. The seat is depicted with the backrest installed.

Hasegawa has not moulded the backrest as part of its cockpit, so the Cutting

Edge set provides some variety in this respect.

The only difference between the sets is the method of

depicting the harness.

The casting block for the tub is connected along the full

length of the rear wall, floor and firewall. Some of these surfaces are

subtly curved, making removal from the block a delicate exercise. I used a

razor saw to remove the bulk of the waste material, then tidied up the

scraps with a sharp hobby knife.

The remaining resin parts are cast onto smaller

blocks.

The sidewalls feature truly exquisite detail. This area is a

particular improvement over the Hasegawa kit. Most of the detail is cast on

with a few exceptions. These are two tiny levers (supplied as separate resin

parts); the throttle cable and upper trim wheel chain, The last two items must

be sourced by the modeller.

The instrument panel is another highlight. It is supplied in

three resin pieces with acetate instruments. Although the instrument detail

is hard to see with the naked eye, it is reproduced perfectly and looks

great under a magnifying glass! The effect of the dials behind the resin

bezels is pretty nice too. The rudder pedals are also up to this high

standard. It is a pity that the comprehensive details on the back of

the pedals will be hidden when the model is finished.

Click the thumbnails below to

view larger images:

The subtly detailed control column, gunsight and breech cover add to the overall appeal of this set.

A separate rubber oxygen hose

is also a nice touch. The fitting for the pilot's end of the hose is

supplied in resin. This part is tiny, even in this large scale, and aligning

the resin fitting to the end of the hose is a serious challenge. Cutting

Edge recognises the risks - three spare fittings are supplied.

Cutting Edge chose to use the two-piece plastic trim wheel

from Hasegawa's kit. This delicate and accurate kit part is worthy of

Cutting Edge's resin. I'll bet it is easier to clean up than a resin part

would be too.

The cast-on harness in set CEC32083 is realistically draped

and should look great after painting and an oil wash. The innovative harness

in set CEC32090 is supplied in flexible resin. I have seen similar resin used

as Zimmerit sheets on armour models, but it is the first time I have seen

the material used for this purpose. The seat belts are moulded into the

flexible sheet

and must be carefully cut out before use.

The modeller is required to add a few details from scratch including the

canopy release handle and prominent ultraviolet instrument lighting. These

lights varied in

style and mounting position, so check references carefully.

Instructions are typical of other Cutting Edge releases.

Photographs of the kit parts and reference pictures of the real aircraft

support detailed construction notes on a two-sided, letter sized

sheet.

Click the thumbnails below to

view larger images:

I did not really need an excuse to build a second Hasegawa

Bf 109G-6, but the arrival of Cutting Edge's cockpit set got me started

straight away.

I have been very happy with the effect conveyed by seat

belts cast on to resin seats, but I decided to tackle Cutting Edge's set

with the unique flexible resin harness this time.

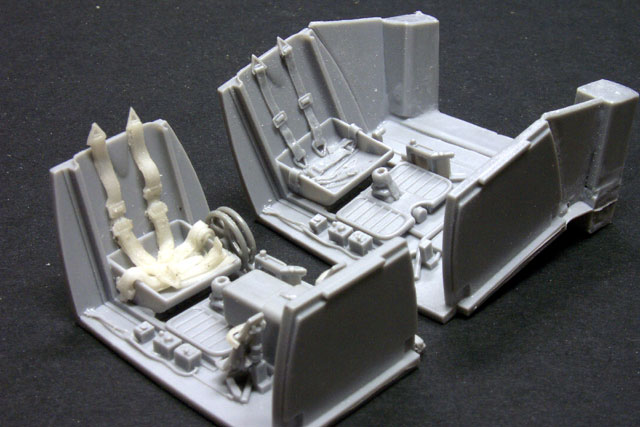

Preparation

Careful cleanup and preparation is always crucial when working with resin.

The biggest casting block was on the cockpit tub. This bulk

of this block was removed using a razor saw, and the remainder was trimmed

off with a hobby knife. Other resin parts were removed by simply slicing

them off or repeatedly

scribing along the join line with a sharp knife until the piece came free.

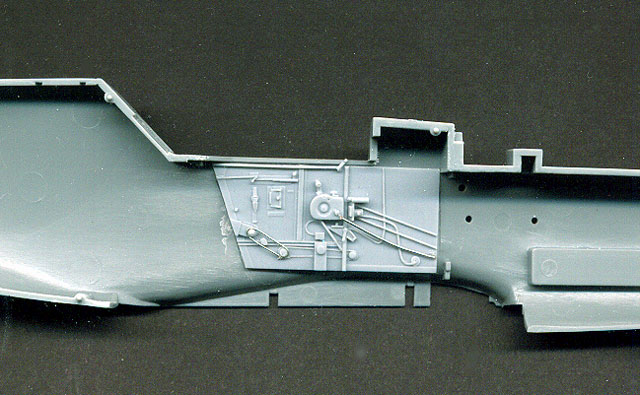

Raised detail must be removed from the kit's fuselage interior to

permit the resin sidewalls to be glued in place. I slipped a grinding wheel

in my Dremel Motor Tool and removed all moulded sidewall detail below the

upper cockpit rails. Take care to leave these top rails in place - they will

help locate the resin sidewalls.

I test-fitted the port resin sidewall by pressing small

blobs of BluTack on the back of the part. The cockpit tub was then offered

to the fuselage half with the sidewall tacked in place. I shifted the

sidewall slightly until the tub was aligned with the fuselage locating

points and the sidewall. The tub was then removed and lines were scribed on

the fuselage using the front and back of the resin sidewalls as a guide.

This would assist with precise fitting later on. This process was repeated

on the starboard side.

The fit of these main parts was perfect. No extra trimming

or adjustment was required.

The instrument panel components were thinned on a sanding

block until the wafer of resin covering the back of the dial faces

disappeared. The resulting holes were cleaned up with a sharp knife.

Flexible

Harness

The harness is supplied on a small flexible resin sheet. The

colour and texture of the material is very much like calamari!

The resin is very elastic, so much so that it is difficult

to "slice" in a conventional way. The material tends to stretch as

the blade is dragged along the material even with a new knife. After

experimenting with a few methods, I eventually decided to "chop"

the resin with a short blade. First I cut horizontal slices toward details

that extended beyond the width of the straps (eg buckles, connectors etc);

then removed the belts by following their outline with a firm, downward

chopping motion.

I emphasise here that the blade must be short,

otherwise detail protruding past the width of the belt will be cut off too.

The buckles and connectors are cast onto the belts. I could

not imagine a technique to precisely hollow these parts, so I decided to

paint them "hollow" later.

With the harness parts separated, I attached the chafing

pads to the lap belts and applied a spot of super glue to one of the

mounting points. This was repeated for the other lap belt before more glue

spots were added and the belts pushed into place on the seat pan. At this

stage I thought the belts looked overscale and the belts seemed to be

"floating" in places. I

slipped some more super glue under the belts using the blade of a hobby

knife and prodded the belts hard into the corners of the seat. This greatly

improved the look of the lap belts.

Take note, once you have glued this material in place it stays

glued. It is incredibly responsive to super glue.

The shoulder belts were installed using the same method. A

drop of glue anchored the belts at the top of the seat first, then more

spots of super glue were applied and the belts positioned. Now the seat was

looking good.

Assembly

and Painting

After preparation, assembly was quite

straightforward.

I glued the sidewalls to the fuselage with super glue using

the lines I had scribed earlier as a guide. The two levers were added to the

canopy ejection actuator and below the throttle quadrant. The

"chain" for the trim wheel and the throttle cable were added from

fuse wire. The cannon breech cover, control column and the kit's trim wheel

assembly were secured to the tub.

Toe straps for the rudder pedals are supplied in the

flexible resin material. I added these before gluing the pedals to the tub.

These straps do look too thick. I will probably use scrap material from the

flexible resin sheet (about half the thickness of the "straps")

for this task in future. The rudder pedals were a little fiddly to mount too

- take care to get these parts lined up properly from all angles.

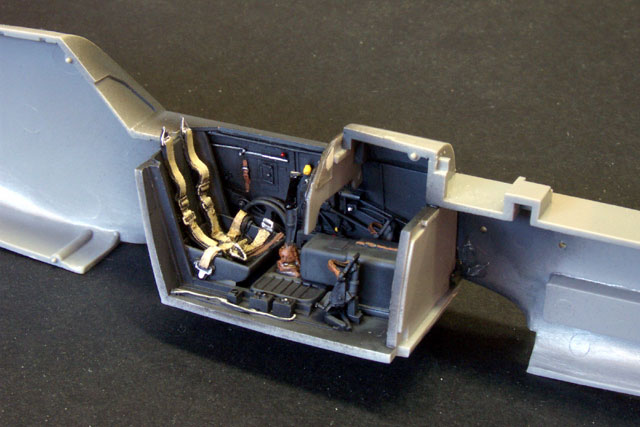

At this stage all the cockpit parts were painted black,

followed by a light coat of Tamiya XF-63 German Grey. I drenched all the parts in

a thin black oil wash. After a half hour, I wiped the excess wash

from the resin parts with a clean cloth and a Q-Tip.

The oxygen hose was cut to 2.5cm and one end was dipped in

super glue accelerator. While it was still on its mount, I applied a tiny

drop of super glue to the end of the oxygen hose fitting with the tip

of a hobby knife. I carefully brought the hose and the fitting together for

an instant bond. The hose fitting, now connected to the hose, was then

sliced off its mounting block. This little assembly was glued to the front

of the throttle quadrant using the same technique as the fitting - the

throttle had a spot of super glue applied, the end of the hose was dipped in

accelerator.

The back of the acetate instruments was painted white. These

were sandwiched between the three panels. The effect is very authentic.

Click the thumbnails below to

view larger images:

|

|

|

|

The sidewalls have been painted German Grey, then given a wash using thinned black oil paint

|

|

|

|

Details are picked out in yellow, silver, red and semi-gloss black with a fine paintbrush.

|

|

|

|

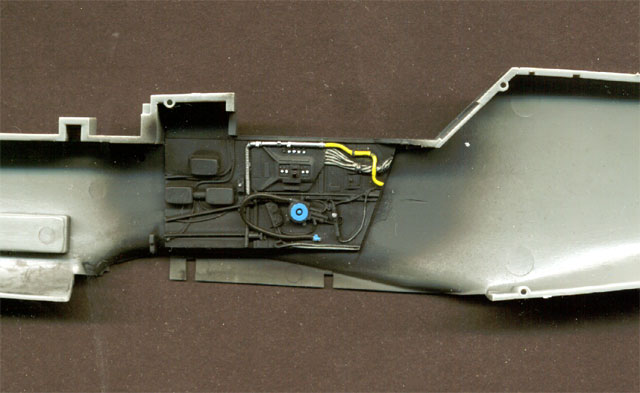

The main cockpit tub assembly gets the same treatment. It is painted and washed after assembly.

|

|

|

|

The details here are picked out too. The harness is painted Tamiya XF-55 Deck Tan and given a further wash in thinned Raw Umber oil paint.

|

|

|

Details were now picked out with a fine brush in silver,

yellow, red, white and semi-gloss black.

Finally, the harness was painted with Tamiya XF-55 Deck Tan. When dry,

I applied a liberal wash of Raw Sienna oil paint. I wiped the paint off the

high points of the harness with my finger, then painted the buckles and

connectors silver. The visible portions of the chafing pads were painted

brown. Although the raw belts do look a little thick, careful painting

really gives them a convincing, three-dimensional look.

With the paint job finished, the instrument panel

and cockpit tub were fitted to the port fuselage side. I ran a bead of super glue along

the front and back of the tub where it met with the kit fuselage to ensure a

secure bond. Finally, the fuselage halves were joined, trapping the Cutting

Edge cockpit permanently.

Cutting Edge's resin cockpit set undoubtedly improves

Hasegawa's excellent 1/32 scale Gustav. The resin parts are beautifully

detailed, the seat backrest makes a change from the kit configuration and

the harness is very obvious in this large scale.

For a direct comparison you can

click here to see

my article on building the Hasegawa kit straight from the box. I used

the same basic painting techniques to finish the standard kit cockpit that I

used here, so the comparison is valid

I was delighted with the final effect of the flexible resin

harness. It requires more effort than the cast-on version, but it does look

impressively three-dimensional and it guarantees an individual result every

time. This harness also offers the option of draping the shoulder belts over

the cockpit sill - something seen in wartime photos from time to time. It is

nice that Cutting Edge have still provided the option of cast-on harnesses

though. This set should also look great. I was delighted with the final effect of the flexible resin

harness. It requires more effort than the cast-on version, but it does look

impressively three-dimensional and it guarantees an individual result every

time. This harness also offers the option of draping the shoulder belts over

the cockpit sill - something seen in wartime photos from time to time. It is

nice that Cutting Edge have still provided the option of cast-on harnesses

though. This set should also look great.

I spent a total of around six hours preparing, assembling

and painting Cutting Edge's resin cockpit for Hasegawa's 1/32 scale

Messerschmitt Bf 109G-6. As far as I am concerned, it was a good investment

of time!

- Highly Recommended.

Thanks to Meteor Productions for the review samples.

Cutting Edge Modelworks products are available from

Meteor Productions Website

HyperScale is proudly sponsored by

Squadron.com

Text and Images Copyright © 2002 by

Brett T. Green

Page Created 14 January, 2002

Last updated 09 November, 2003

Back to HyperScale

Main Page

Back to Reviews Page

|

Home | What's

New | Features

| Gallery |

Reviews | Reference

| Forum

| Search