|

Saunders

Roe P177R

Freightdog Models,

1/72 Scale

S u m m a r y

|

|

Catalogue Number: |

Freightdog Models

Saunders Roe P177R |

|

Scale: |

1/72 |

| Contents and

Media: |

25

parts in cream coloured resin; two clear vacform parts;

speculative markings for six aircraft. |

| Price: |

GBP£33.00 available online from

Freightdog Models website |

| Review Type: |

FirstLook |

| Advantages: |

Interesting subject;

excellent casting; almost flawless fit; good level of

detail; high quality "what-if" decals |

| Disadvantages: |

A few air bubbles here

are there. |

|

Recommendation: |

Highly Recommended |

Reviewed by Brett Green

HyperScale is proudly sponsored by

Squadron.com

Freightdog Models released their 1/72 scale Saunders Roe P177R mixed-power

fighter project aircraft at IPMS ScaleModelworld last weekend.

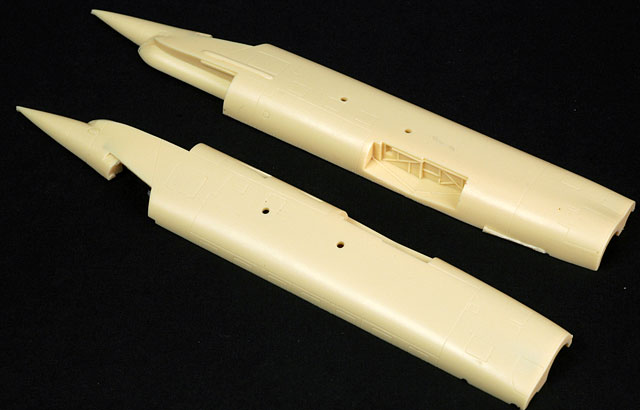

The model comprises 25 beautifully cast yellow resin parts, plus a vacform

canopy (and a spare). The high level of casting is not surprising as the

parts have been produced by Anigrand Craftworks in Hong Kong. There were a

few air bubbles that need to be filled on my sample, but this was a fast and

easy task.

Click the thumbnails below to view larger

images:

Rockets and drop tanks are supplied, as is a nice ejection seat. The seat

is the full extent of cockpit detail.

Wheel well detail is cast in place on the fuselage halves.

Very little cleanup of the resin parts is required before construction

begins.

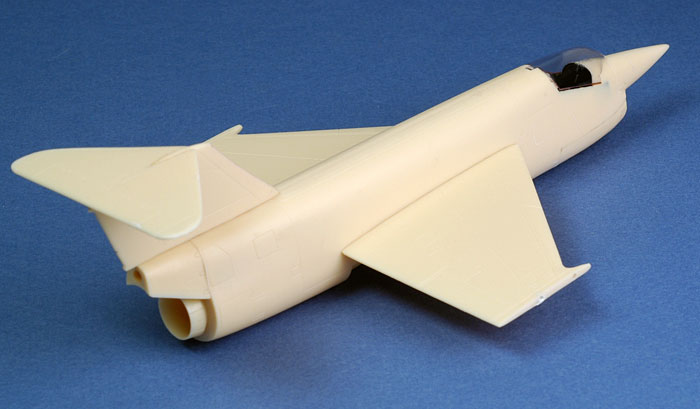

The kit is cleverly engineered to help ensure secure fit of major parts.

The fuselage has locating holes for the wings and the fin, and the

horizontal tailplanes slot into the top of the fin for a secure bond.

Markings for six speculative aircraft are supplied, but with the real

aircraft never having been completed you can please yourself about the

finish of your model. These attractive markings will provide ample

inspiration, however. The decals are printed by Fantasy Printshop, and are

thin and in perfect regsiter.

Construction Underway...

When I received my early production sample some months ago, I did not

really intend to build the model immediately. I was just going to test fit

the parts.

As it turned out, preparing the parts was so easy that I thought I might

glue a few components together. The fit was so good that I just kept going!

I only have a few comments and suggestions about

construction:

Do take a few minutes to check

for pin holes and air bubbles. On my sample, there were a few on the

fuselage and wings, and more noticeably on the drop tanks. These were filled

with Milliput and sanded smooth when set.

The vacform canopy is very thin.

If you are securing it in the closed position, I recommend gluing a fine

bead of copper wire (or plastic sprue, or fuse wire, or any similar

material) to act as a positive lip to glue to the inside edges of the canopy

part.

If you are building the aircraft

with the wheels down, remember that the intake lip would have been extended.

My early sample did not come with instructions so I did not discover this

detail until it was too late!

I have not yet added nose

weight. I have not glued the jet nozzle in place, so I can add small lead

pellets iside the fuselage if required.

Otherwise, construction has been very straightforward.

Fit is almost flawless. No filler has been applied to joins

in these photos. However, I did manage to slightly misalign the join on the

bottom of the rear fuselage. This step was filled with Milliput and sanded

flat when set.

I look forward to completing and painting the model now that

I have received the decal sheet. A full Feature Article will be posted to

HyperScale when I have finished.

Text and Images Copyright © 2006 by Brett Green

Page Created 24 November, 2006

Last updated 21 February, 2007

Back to HyperScale Main Page

|

Home | What's

New | Features

| Gallery |

Reviews | Reference

| Forum

| Search