|

USS Enterprise NCC-1701

Bandai

HyperScale is proudly supported by Squadron.com

S

u m m a r y

|

| Catalogue Number: |

0116192 |

| Scale: |

1/850 |

| Contents and Media: |

56 parts in pre-painted plastic plus

lights, cables and electrical fittings. |

| Price: |

¥6,500 (purchased from Japan) |

| Review Type: |

Construction |

| Advantages: |

Truly spectacular pre-painted

plastic; brilliant engineering; brings this science fiction subject to

life; includes clever lighting to main elements of the model; no glue

required; display stand included (integrating batteries and switch) plus

panels to close off mounting hole in model. |

| Disadvantages: |

Variable quality fit (95% excellent;

5% incredibly frustrating); some major joins do not cope well with

punishment of construction; very fiddly and cramped main junction for

electrical cables; brute force required to make some parts fit; external

wiring to warp nacelles. |

| Recommendation: |

Recommended to patient modellers |

Built and Reviewed by

Brett Green

A snap kit? Pre-painted?

Yes indeed, but don't panic. Bandai's 1/850 scale USS Enterprise

is like no other snap kit you have ever seen.

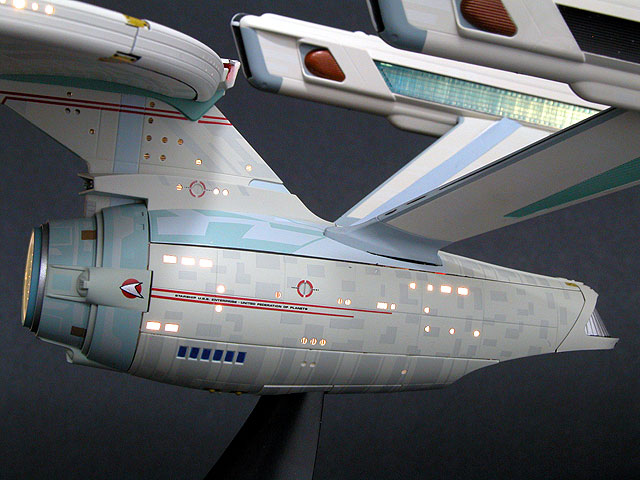

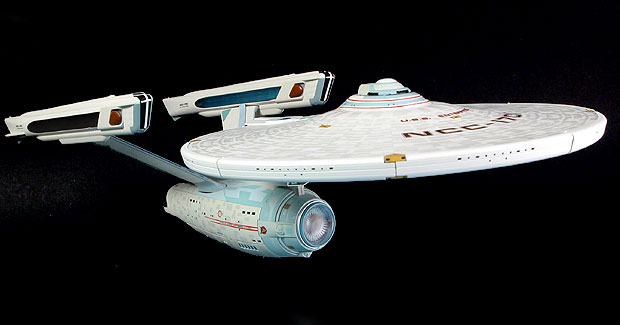

The kit includes 56 parts in injection moulded plastic. Most of

the parts are pre-painted polystyrene, but there is also a mix of clear and

tinted plastic. Some of these parts seem to be a different plastic compound

(polyethylene perhaps). Panel lines, if that is the correct term, are fine,

crisp and consistent even in this small scale.

The quality of the painting and markings of the plastic parts is

absolutely stunning.

It is important to note that this is not coloured plastic

- the entire exterior surfaces of the parts have been painted. The

characteristic Aztek pattern is both subtle and amazingly involved. The pattern

is achieved more with varying texture and gloss levels rather than any

consciously noticeable colour difference. It is very impressive. The

coloured panels add variety and look great in the box and on the completed kit.

The markings are sharp and totally free of any imperfections. The overall

standard of finish is far better than most modellers (including myself) would be

able to achieve after a week of non-stop masking and spraying.

In addition to the basic shape of Enterprise, the kit also

includes six light bulbs, cables and various electrical fittings to permit all

the major elements of the model to be realistically lit.

At around 36cm long, the assembled model is not especially big

but detail is still easily visible.

Construction

I heard two reports that this kit could be built in a very short

time. Scott T. Hards from Hobbylink Japan finished his Enterprise in three

hours, and Dave Williams told me that he had finished his in four hours. Dave

commented that the model needed some adult size strength and swear words to get

it together though. His observation was prophetic!

I fancied the idea of a pleasant evening diversion, so I cleared

the workbench and started work.

It was quite easy to remove and clean-up the parts from the

sprues, but care is required not to damage the paint finish on the outside

surfaces. Bandai has helped here by moulding the sprue connectors on the inside

edge of the part wherever possible.

The base, incorporating the battery box and switch, was

assembled first then all the cables were cut to length. A word of advice here -

do not cut the cables longer than the template or you will not be able to stuff

the excess inside the kit parts. Next, I tested the bulbs with a single AA size

battery. No problems so far.

Assembly of the warp nacelles and saucer section went ahead very

well. I ended up with a largish seam on the bottom of each nacelle but these

cannot be seen from most angles.

I was not entirely happy with the fit of the nacelle support

pylons, and these continued to be troublesome through the rest of construction.

Also, the wiring is exposed along a recessed channel on the inboard surface of

the pylons. Instructions suggest that a self-adhesive covering strip is applied

prior to final assembly of the secondary hull, but I strongly advise leaving

this until everything else is finished.

One of the warp nacelles fell off its pylon when I started

working on the electricals in the secondary hull. When the nacelle fell off it

also stripped off the self-adhesive cover, and pulled out a few extra

millimetres of of wire. It was quite a challenge to feed the wire back into the

nacelle and I could not refinish the cover strip smoothly. That same nacelle

fell off about ten more times during remaining assembly.

All of the electrical wires come together in a central junction

inside the secondary hull. I found it fiddly to thread and tie the wires through

the tiny holes in the connectors. The next challenge was getting the secondary

hull sidewalls and bottom of the hull to fit. I had to disassemble and

reassemble the whole secondary hull a few times before I was satisfied with the

fit. In the end, there was still a fairly big gap on the top of the port

sidewall.

The fit at the hull top with each warp pylon was not especially

good on my kit either.

It should be noted that a fair amount of brute force is required

set these pieces in place, but extreme care must be taken to get all the tabs

located correctly first, and to follow the sequence of the instructions to

the letter. Otherwise, you will risk bending or breaking a locating tab -

then you'll really be in trouble!

With the kit now assembled, I added batteries and slotted the

model onto the base. I was ready to turn on the lights. Drum roll please...

switch on...

Nothing.

I assumed that I had crimped a cable while I was repeatedly

reassembling the nacelle and hull, or possibly disconnected something from the

main junction with the force of assembly, or screwed up in some other way.

However, I decided to eliminate one possible problem. I connected some loose

wires to a battery, then touched them to the contacts in the bottom of the hull.

Voila! The ship lit up! The problem must have been in the base.

I dismantled the base and found that one of the connectors in

the top of the base was not touching the steel strap in the vertical section. I

bent the contact upward to improve contact and the lighting worked perfectly.

Construction took between four and five hours, even with the

troubleshooting and self-imposed problems.

In my opinion, the Bandai 1/850 USS Enterprise kit is a

fascinating example of what might become a significant direction for our hobby

in the forseeable future, and not just in the realm of science fiction.

On the one hand, the quality and complexity of today's injection

moulded kits is constantly rising. This is great for experienced modellers, but

it must be intimidating to the new or casual hobbyist.

On the other hand, die-cast model aircraft and vehicles have

mushroomed in the last few years. Many of these pre-assembled and pre-painted

kits pass the test at a distance of four feet, but details and finish is still

quite crude compared to their injection moulded plastic counterparts.

Imagine a company like Bandai turning its attention to, for

example, modern US Navy aircraft for inspiration. How about an F-14, pre-painted

and pre-marked, with perfectly applied patchy weathering and snap-fit

engineering permitting completion in 3 to 4 hours.

It might not be an attractive idea to us crusty old modellers

who yearn for paint vapours, procrastination and polystyrene cement; but it

might be an a logical step between die-cast collectibles and conventional

scale model kits.

Bandai's 1/850 scale USS Enterprise is a remarkable and

ambitious model. The finish is truly spectacular even though I was frustrated by

some elements of construction.

I do hope that we see perhaps a non-electrified version of this

kit; plus more variants of the Enterprise (and Voyager too) from Bandai in the

future.

It will be interesting to see how Bandai goes boldly where no

model company has gone before!

Recommended.

P.S. My wife has been devoutly and

consistently unenthusiastic towards anything related to models over the years. I

can't blame her really.

However, when I trotted out

Enterprise and turned on the lights, she actually said "Wow, that's great!".

Even more encouraging, she immediately wanted to turn out the room lights to see

how the model looked under its own illumination.

As far as I am concerned, that

is an endorsement that money can't buy!

Model, Review Text and Images Copyright © 2003 by Brett

Green

Page Created 13 May, 2003

Last updated 09 November, 2003

Back to HyperScale Main Page

Back to Reviews Page

|

Home | What's

New | Features

| Gallery |

Reviews | Reference

| Forum

| Search